As the world slowly transitions from internal combustion engine vehicles to electric vehicles, one of the components that has been a key driver of this change is the motor.

Most electric vehicles use permanent magnet motors which offer 90% efficiency and hence considered the best bet currently.

However, permanent magnets are made of several alloys which also include rare earth minerals, and this pose a bunch of challenges. Bengaluru-based deep-tech start-up Chara Technologies is trying to devise a solution to this by developing motors that are free of rare earth minerals.

The journey

“‘Chara’ means motion,” explains Mahalingam Koushik, co-founder and CTO of the start-up.

“The world is transitioning from a fossil fuel-based energy economy to electron energy economy. The key driver in the new energy economy which converts electricity into mechanical energy will be a motor. This is the space we are trying to provide a solution in.”

When Koushik and Bhaktha Keshavachar (CEO of Chara) came together to build a new venture, the idea was to develop something for the EV segment which has been growing and hence would need new technologies. They noticed that motors offered a possibility of innovation as most motors and controllers were being imported.

Ravi Prasad, Chief Motor Designer at Chara, soon joined the duo, and the company was registered in 2019.

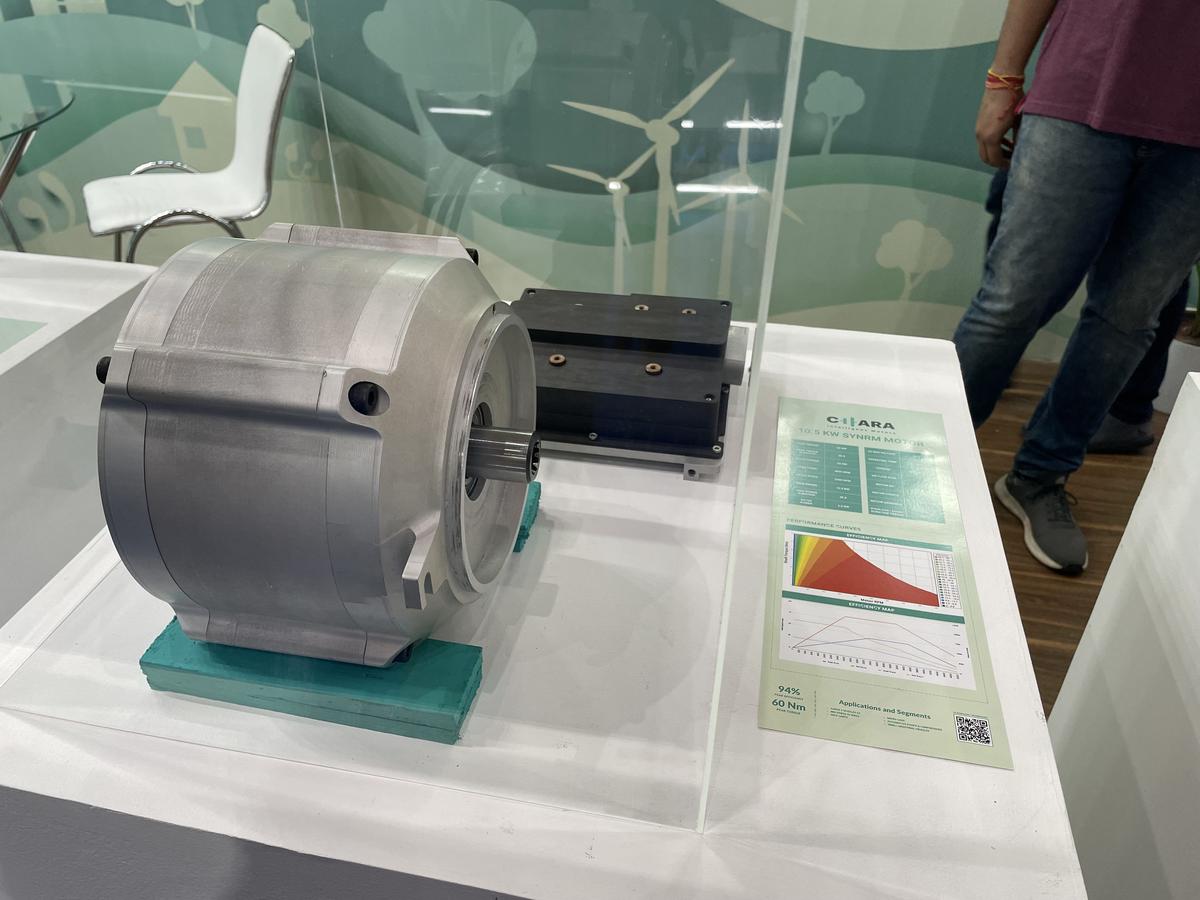

Tarwan motor.

| Photo Credit:

SPECIAL ARRANGEMENT

The context

Depending upon the type of application, two types of motors are used generally – induction motors and permanent magnet motors.

Induction motors which are widely used in household appliances have around 70% efficiency on average.

Permanent magnet motors offer much higher efficiency of 90% but are costlier and the rare earth minerals used in these are difficult to mine and extract. This results in supply chain limitations and inconsistencies in the availability of the material.

Yet another challenge is that 90% of its extraction is controlled by China which makes manufacturers heavily reliant on one country.

“Rare earth minerals are called so not because they are rare, but the content of each element in the ore is very less,” explains Koushik.

Elements like Neodymium and Dysprosium are used in motors, but in a ton of ore, only a few grams of each can be found.

“These elements are all found together because they are very similar in atomic weight and size. So, extracting them from each other takes a lot of chemical processing and chemical leaching agents. Also, some of the rare earth elements are radioactive, and produce radioactive waste. So, ecologically it is not scalable.”

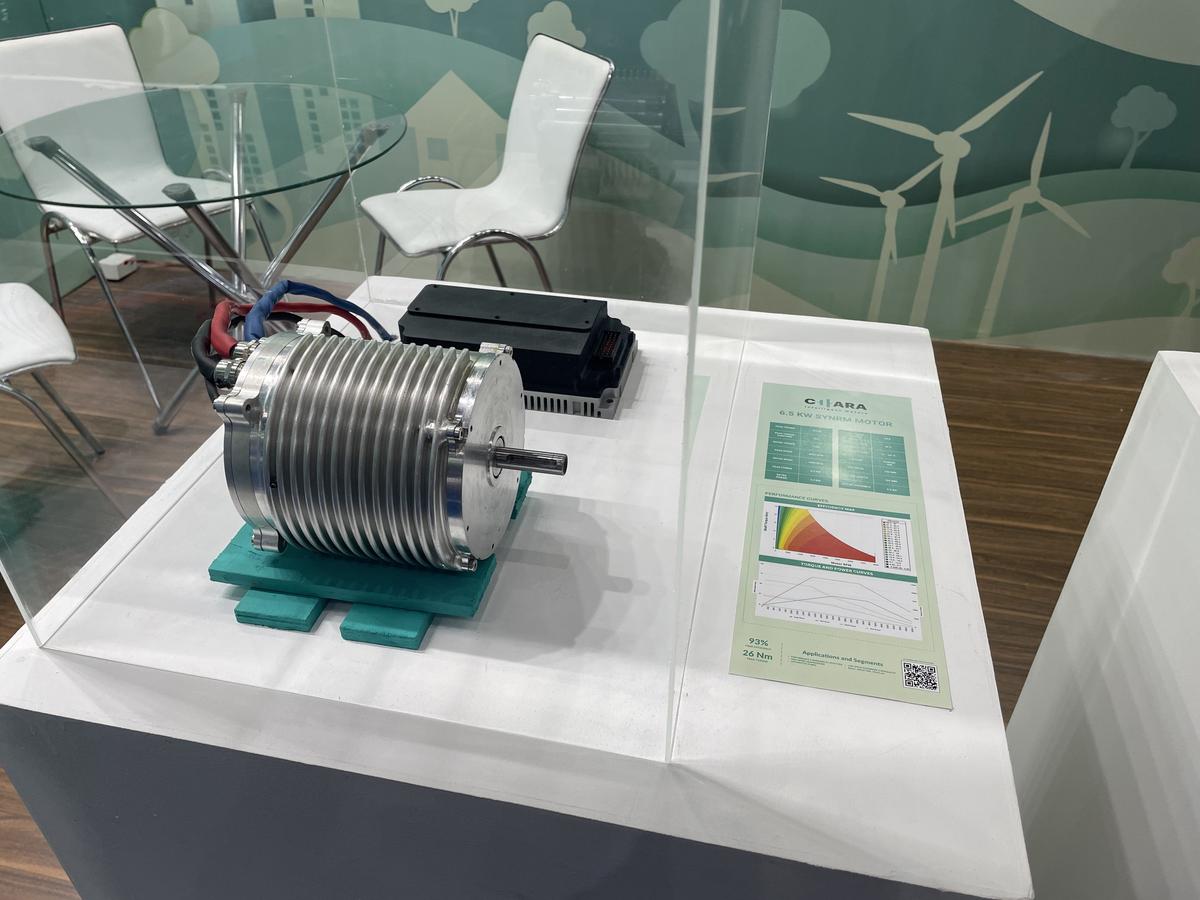

6kW 48-96V Motor and ramp Controller showcase.

| Photo Credit:

SPECIAL ARRANGEMENT

Chara’s technology

Chara’s motor has been designed based on synchronous reluctance motor technology which according to the team helps them to build motors which perform as good as permanent magnets but without the price concerns associated with the latter.

“Depending on the power rating, we will be anywhere 15-30% cheaper than permanent magnet motors,” Koushik claims.

The start-up’s offering includes the motor, the controller which drives the motor, and the software.

“We have done a lot of innovation in the motor design, controllers and controller algorithms. We have achieved very good power density and smooth performance. These motors and controllers have been tested in labs as well as in vehicles on the road,” remarks Koushik.

The team is also developing a cloud platform where data collected from the motors and controllers would be used for analytics and in building a digital twin which will then help to do predictive dynamics, diagnostics and improvements on the product.

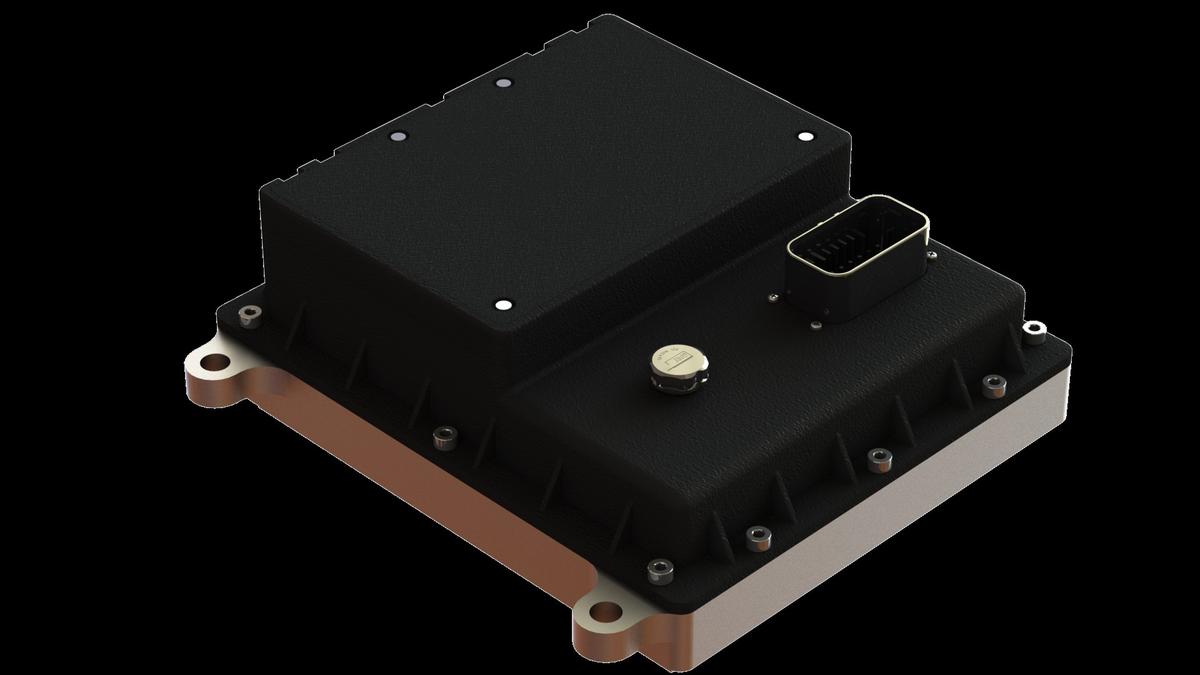

Akash controller.

| Photo Credit:

SPECIAL ARRANGEMENT

Multiple applications

The company has currently developed motors for two wheelers, three wheelers (passenger as well as cargo) and four wheelers like commercial vehicles and tractors.

The team is also building a 125-kilowatt peak motor suitable for a mid-size SUV. While some of the manufacturing is done inhouse, a part of it is outsourced.

“Today most of the motors and controllers are being imported or manufactured locally by established MNCs. There is limited end to end localised development and manufacturing, which is what we are doing.”

“We develop the products end to end – the motor design, electromagnetic design, mechanical design, thermal design and structural analysis; And then when it comes to the controller, electronics design, thermal design, mechanical design for the enclosure and the heat sync, and the software that runs on the controller,” says Koushik who notes that this helps the team to have a better control over design and supply.

3.5kW 48-96V Motor and amp controller showcase.

| Photo Credit:

SPECIAL ARRANGEMENT

Further improvements

He, however, admits that the journey has not been without challenges. One of the technical challenges that the team had to deal with was the power density problem associated with synchronous reluctance motors.

Power density is the amount of power or energy in a given mass or volume.

“If you look at permanent magnet motors, they have generally a power density of 2.1 kW/kg. For our motors, it is 1.7-1.8 kW/kg. That is one limitation. It is slightly longer and heavier since we have had to use more steel and copper to achieve similar performance,” Koushik says.

This means that the motor will be around 1 kg heavier than the typical ones. However, given it is less than half a percent of the total gross weight of the vehicle, it doesn’t affect the vehicle performance, claims Koushik.

“Due to this limitation, there are certain applications for which our technology is not suitable today, for example in drones where every gram matters. But for anything that sits on earth or moves on the road, this works,” he says, further adding that the team is working on some improvements.

Going forward

While the motor and controller have multiple applications such as EV, industrial use, HVAC and appliances, the Chara team is focused primarily on the EV segment given the novelty of the industry and the growth expected in the segment in the coming days.

“We are also looking at industrial applications where sustainability and efficiency would be important. If people are looking at more on the operational cost, then our motors will be a very good solution.”

The company currently claims to have early orders from 14 different clients, each of whom has ordered about 10-15 of the products. Around 30 units have been shipped so far, says Koushik.

The start-up which received its first grant from the IISc MSME Centre of Excellence raised its first round of funding in 2021. The round was led by Kalaari Capital with participation from IIMA Ventures. In 2022 December it raised another round that was led by Exfinity Venture Partners.

Koushik says, “Now that we have proven the technology, we would like to deploy the motor in large numbers in the coming days. The rare earth mineral problem is not unique to India, it is global problem. So, we would like to build our solutions for the world.”